FactoryOps for

plastics & Packaging

From molding parts to running film, packaging product, and more, Amperon Technologies helps plastics & packaging teams get more from every run.

GREAT PARTNERS HAVE CONFIDENCE IN US

Amperon's Autonomous Production for Plastic Industry

Discover your first steps in Autonomous Manufacturing using Amperon' innovative FactoryOps® which drive quick & deep improvements in your plastic manufacturing processes, from injection molding to extrusion and blow molding.

Key Processes in the Plastic Industry

Injection Molding

High-volume production of complex plastic parts.

Extrusion

Continuous melting and shaping of plastic.

Blow Molding

Fabrication of hollow plastic parts by blowing air into a mold.

Processes such as plastic injection molding, material extrusion, blow molding, rotomolding, thermoforming or combinations of these face four main challenges: production stops, continuous manual supervision, scrap parts and material and high energy costs.

4 Challenges Faced by Plastic Manufacturers

Production stops

Machine breakdown and changeovers cost 60% of total factory losses. Tackling stops is crucial to keep with high demand and to avoid unnecessary investments in new machines.

Continuous manual supervision

Plastic equipments require continuous supervision & tuning of process parameters by expert personnel to avoid quality issues or discards with costs pre-calculations.

Scrap materials & parts

Ensuring minimum start-up, trimming wastes and off-specs parts is critical but difficult to achieve and is labor intensive.

High Energy Consumption

Controlling energy consumption through smart machine-part pairing and minimizing idle time remains a key challenge.

AI FactoryOps® smart solution

delivers you in just One Week

Real-Time Visibility

- •Second by second machine status

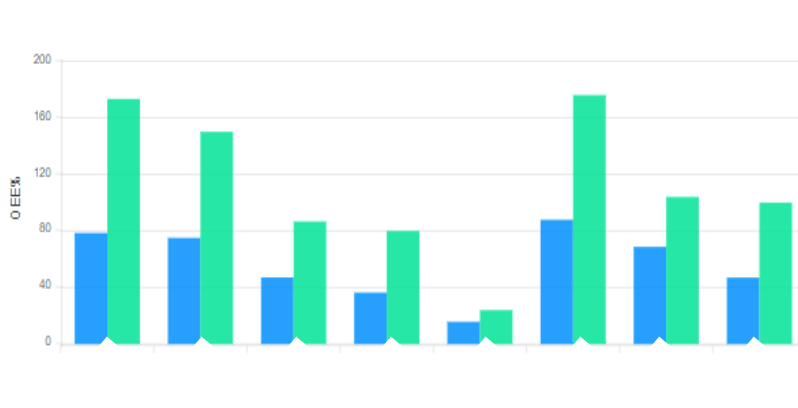

- •Live OEE monitoring for improved machine utilization

- •Monitoring of idle times and inefficient processes

Automatic Anomalies detection

- •Early detection of process deviation

- •Predictive Maintenance

- •Predictive Quality

- •Smart alerts instead of continuous manual supervision

Tracking KPIs & Operations

- •Accurate post-calculations for more effective pricing and negotiations

- •Tracks cycle time, OEE, and energy intensity

- •Operational traceability for compliance and improvement

Optimization Insights

- •Optimization of heating phases, cycle times, and cooling

- •Smart machine-part pairing for operational excellence

3 Steps to Reach Sustainable Peak Performance

Get real-time visibility and insights in minutes — no complex installations required.

1.Clamp

Connect to any machine through low-cost, non-intrusive sensors

2.See

Empower your operators with real-time machine status and AI-powered predictive alerts

3.Analyze

Track and improve manufacturing and energy efficiency KPIs through traceability and root cause analysis

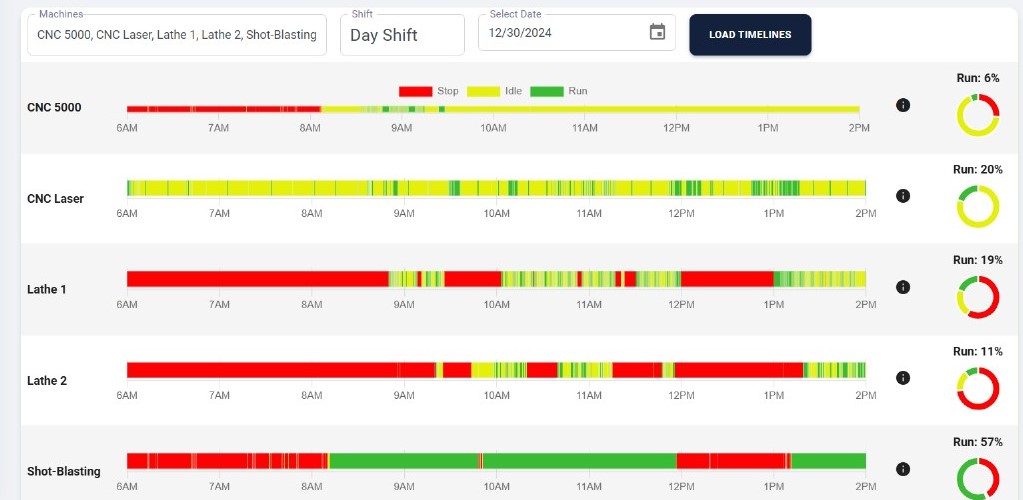

Real Time Machine status

Low-cost data capture, with high reliability and immediacy, which, processed with digital intelligence, allows knowing the real machine status and the elaboration of patterns for each machine/operator.

Evaluation by the end of shift of the real productive time and the lost production time.

Start unlocking the "hidden factory" by identifying current machine utilization.

Make informed CapEx investment through knowing current utilization

Reduce downtime due to changeover / cleaning / no operator…

Through providing context to automatically detected downtime durations (no human intervention), Changeover, Cleaning and other operations can be improved by identifying abnormal durations related to a specific machine, a specific operator , a specific tool and a specific article.

Real Time automatic Parts /Cycle time tracking

Automate your cycle count data collection. no PLC integration needed. No human input required. Every created part can be seen through the power profile or through electrical actuators status.

Detection and alerts of deviations in manufacturing cycle times

Detailed tracking of operations per Cycle

Our technology enables identifying each operation during a complete cycle in order to detect deviations in time duration / power levels which reflect anomalies.

Identify inefficiencies in Cells

Tracking KPIs in long lines where we have different cells or machines connected to understand who originates the highest inefficiencies in the overall line.

Reduce Scrap and uncontrolled process

Critical process variables such as temperatures, pressures, times, are essential to achieve the required quality in each part, so their control in real time is fundamental. Traceability is ensured for every variables 1 Sample/s.

Managers can be alerted in RT if there’s any deviation (accidentally or intentionally) from preset parameters.

Anomalies can be linked to process variables, So it can be used to train AI based Quality detection models.

Real-Time anomalies detection during plastic transformation

Power profiles reflects anomalies during the process of plastic transformation. Operators can detect in time issues related to a defect in the mold, a malfunction of the actuator or an incorrect plastic melt.

Having immediate knowledge of overconsumption, scrap, defective parts, abnormal feeding etc., allows avoiding big losses

Avoid Hydraulic units / Electric drives breakdown

Identify early signs of fault within Hydraulic units / Electric drives.

Drive continuous improvement at scale

Expand to more lines and sites, track plant-wide OEE, and layer on insights to drive better performance over time.

What to expect from FactoryOps®

Expected impact with ROI in "2 months"

-40% to -70% Stops reduction through early detection of breakdown / bottlenecks and killing downtime causes.

-30% reduction on scraps costs

+15% production speed by uncovering hidden performance losses.

-20% reduction of labor costs related to quality inspection and machines supervision

-30% carbon emissions by avoiding unproductive consumption.

Financial control of production runs according to pre-calculations

90% pricing accuracy during negotiations

Potential Savings:

ROI in just 2 months

Fast return on investment guaranteed

Key Takeaways

Real-Time Operational Improvements

Real-Time Machine Data Visibility at the lowest costs creates many opportunities for quick wins

Quality Defect Identification and cycles count are easily obtained in Real Time

During production knowledge of cycles characteristics enables huge savings

Significant cost savings are now possible by part related energy consumption

Workforce costs are reduced by smart early alerts on process inefficiencies

Machine/ Molds breakdowns are avoided with Digitized Maintenance

Operational Impact:

Rapid Value Realization

Quick wins and continuous improvements

Ready to take your operations to the next level?

Let's talk about how Amperon Technlogies can help your team reduce downtime, boost output, and drive performance across every line, shift, and site.