FactoryOps for

Aeronautics & CNC Machining

Take your first steps into Autonomous Manufacturing with Amperon’s innovative FactoryOps®, designed to deliver rapid and lasting improvements across your machining operations — from the oldest manual lathe to the most advanced 5-axis CNC machine

GREAT PARTNERS HAVE CONFIDENCE IN US

Amperon's Autonomous Production for Aeronautics & CNC Machining Industry

Discover your first steps in Autonomous Manufacturing using Amperon' innovative FactoryOps® which drive quick & deep improvements in your machining processes, from your oldest manual lathe to your newest 5 axis CNC machining.

Challenges Faced by Aeronautics & CNC Machining Manufacturers

Lack of visibility into operations

Inability to pinpoint in Real-time and with accuracy job status and why/where downtime was occurring. This results in unhappy customers and ineffective improvement actions.

Complex Machines / tools

machining equipment and their tools require dedicated care since they affect productivity and quality. Managers have no idea in Real-time about tools anomalies or non-realized hour-based service operations

Quality Control Challenges

Ensuring consistent product quality across production runs is critical but difficult to achieve. Delayed detection of non quality in costly pieces generates a lot of subsequent unnecessary costs.

Energy Consumption Constraints

Ensuring that energy consumption is controlled for each part manufactured is a critical challenge. Managers still pay for unnecessary energy related to auxiliary systems while machining is off.

AI FactoryOps® smart solution

delivers you in just One Week

Real-Time Visibility

- •Provides real-time data on machines, operations execution and all issues.

Automatic Anomalies detection

- •Anticipates equipment issues to minimize downtime and disruptions.

- •Track execution of auto-maintenance actions.

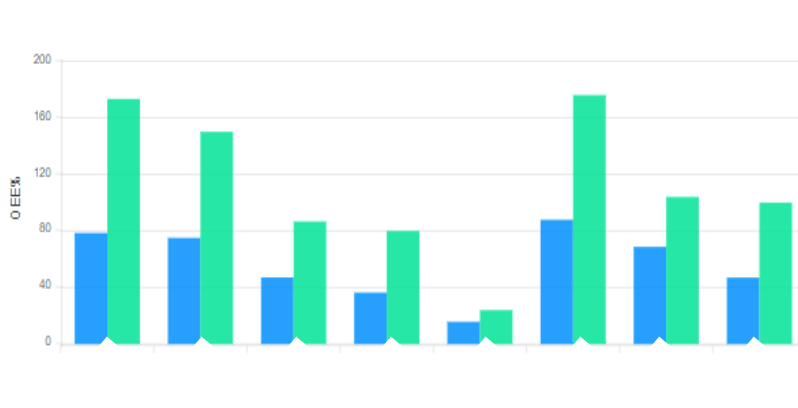

Tracking KPIs & Operations

- •Tracks and analyzes key performance indicators (OEE, Energy Intensity,…) and operations.

Optimization Insights

- •Identifies opportunities to improve efficiency and productivity.

3 Steps to Reach Sustainable Peak Performance

Get real-time visibility and insights in minutes — no complex installations required.

1.Clamp

Connect to any machine through low-cost, non-intrusive sensors

2.See

Empower your operators with real-time machine status and AI-powered predictive alerts

3.Analyze

Track and improve manufacturing and energy efficiency KPIs through traceability and root cause analysis

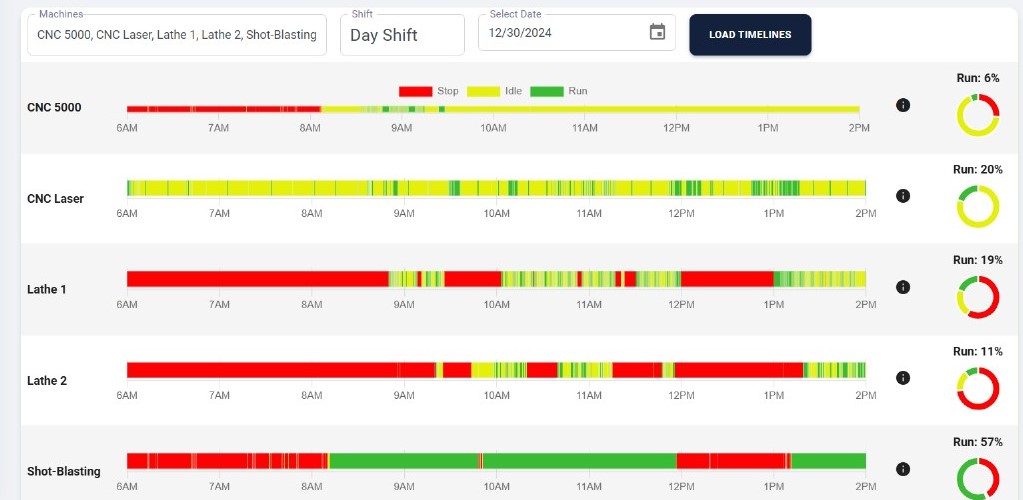

Real Time Machine status

Low-cost data capture, with high reliability and immediacy, which, processed with digital intelligence, allows knowing the real machine status and the elaboration of patterns for each machine/operator.

Evaluation by the end of shift of the real productive time and the lost production time.

Start unlocking the "hidden factory" by identifying current machine utilization.

Make informed CapEx investment through knowing current utilization

Reduce downtime due to changeover / cleaning / no operator…

Through providing context to automatically detected downtime durations (no human intervention), Changeover, Cleaning and other operations can be improved by identifying abnormal durations related to a specific machine, a specific operator , a specific tool and a specific article.

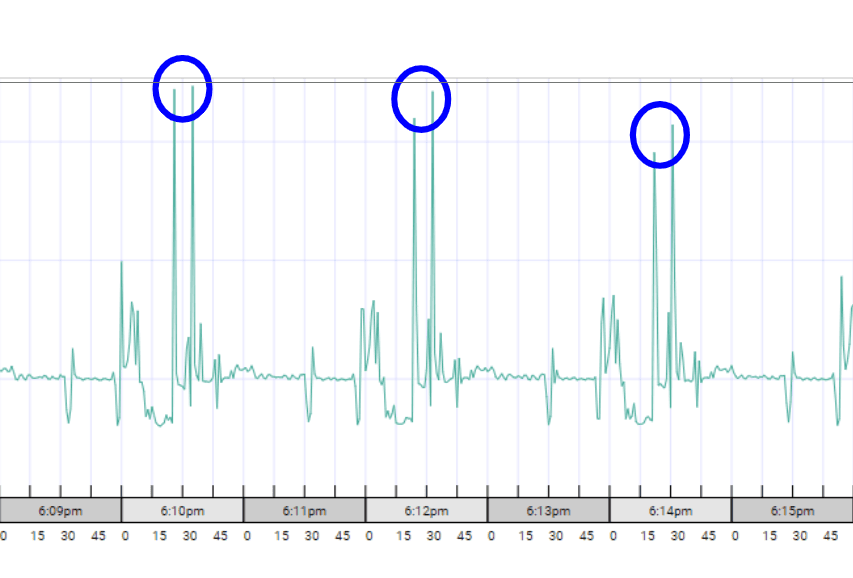

Real Time automatic Parts /Cycle time tracking

Automate your cycle count data collection. no PLC integration needed. No human input required. Every created part / cycle (or phase transition in A/B pallet) can be seen through the power profile or through electrical actuators status in machine panel.

Detection and alerts of deviations in manufacturing cycle times

Identify inefficiencies in Cells

Tracking KPIs in long lines where we have different cells or machines connected to understand who originates the highest inefficiencies in the overall line.

Avoid Hydraulic units / Electric drives breakdown

Identify early signs of fault within Hydraulic units / Electric drives.

Use case from High precision machining manufacturer in Aeronautic sector

- Uses machine status RT visibility (Essential Pack)

- Hardware installation for 8 machines in 2 days

- Solution configured and deployed next Monday

- Heterogeneous CNC machines (Legacy and brand new)

- Average Utilization rate at the beginning 45% with 20% idle (wasted energy and no production)

- After 2 months: shopfloor utilization rate at 55% and 5% idle

Use case 1: Long check procedure detection and energy wastage

- Detect (from the second day after Amperon’s FactoryOps installation) late start coupled with long procedure of quality check between shifts for the same article. This pattern was confirmed over the week.

- Quality procedure takes between 30min to 1h (approx 12.5% of the shift)

- The same downtime shows an big wastage in energy (5A during 1 hour each shift) due to auxiliary units.

- Improvement actions was taken to optimize the check duration without affecting quality resulting in a 5% gains in utilization. Shutting down machines during checks reduced energy bill by 9%.

Use case 2: Micro-stops between cycles

- Detect unplanned micro-stops between each article for a specific CNC lathe type.

- The quantified micro-stps costs the customer between 30 min and 45 min per shift .

- Investigations highlight that the lack of operator training leads to the non use of article recovery system which causes these micro-stops.

- Required training actions was taken, resulting in regaining of 6% of utilization for all Lathes in the shop-floor in just one week.

Use case 3: Improper productivity identified

- Detect strange production behaviour in the last hour of each shift for several CNCs. This pattern was confirmed for a specific operator.

- The quantified low performance revealed a waste of 30% of productivity performance each shift for this operator.

- Required actions was taken, resulting in improved productivity by 15% for this operator.

- Action plan reduced downtime with better scheduling.

Key Takeaways

Real-Time Operational Improvements

Real-Time Machine Data Visibility at the lowest costs creates many opportunities for quick wins and ROI under 1 month.

Automatic item count and Cycle determination are key informations to avoid delivery delays.

Inefficiencies are easily linked to tools / machines / operators.

Tiny micro-stops are quantified to reveal need for operator training.

Significant Cost Savings are possible by identifying wasted energy

Machine breakdowns are avoided with Digitized Maintenance

Operational Impact:

Rapid Value Realization

Quick wins and continuous improvements

Ready to take your operations to the next level?

Let's talk about how Amperon Technlogies can help your team reduce downtime, boost output, and drive performance across every line, shift, and site.