FactoryOps for

Pharmaceutical Sector

Drive efficiency in pharmaceuticals production Ensure regulatory compliance, minimize production downtime, and maintain the highest quality standards with Amperon’s AI-powered FactoryOps platform. Optimize your pharmaceutical manufacturing processes to drive efficiency, consistency, and operational excellence.

GREAT PARTNERS HAVE CONFIDENCE IN US

4 Challenges Faced by Pharmaceutical Sector

Pharmaceutical companies lose

50% of their Revenuedue to their inability to tackle Unplanned Downtime, Production low performance and Bad product quality

Unplanned Downtime

60% of total losses costs 2000 $ per hour per machine the minimum cost from unplanned downtime in pharmaceutical industry (regulated environment, labor cost, quality issues,...)

Manual Data Burden

Impossible to predict or diagnose anomalies with manual tracking

The Need for Real-Time Data-Driven decisions

Managers & Teams need Real-Time visibility on Production Operations

FactoryOps for Pharmaceutical Sector

Amperon's FactoryOpS

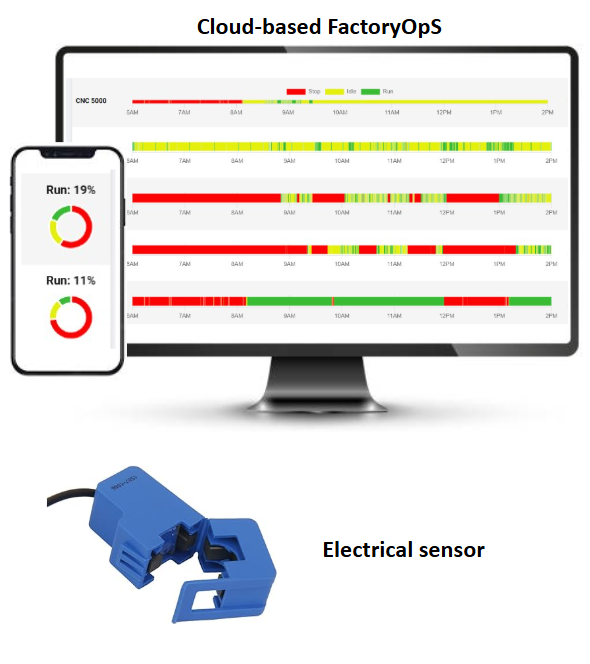

Low-cost Real-Time visibility and anomalies prediction without compliance issues or human expertise using just the Electrical signals of machines.

3 Steps to Reach Sustainable Peak Performance

Get real-time visibility and insights in minutes — no complex installations required.

1.Clamp

Connect to any machine through low-cost, non-intrusive sensors

2.See

Empower your operators with real-time machine status and AI-powered predictive alerts

3.Analyze

Track and improve manufacturing and energy efficiency KPIs through traceability and root cause analysis

...and many more !

Your solution for pharmaceutical manufacturing

Amperon Technologies provides pharmaceutical manufacturers with powerful real-time monitoring AI-Powered FactoryOps to enhance production efficiency, ensure regulatory compliance, and maintain strict quality control. By offering complete visibility into production processes, Amperon helps identify inefficiencies, reduce downtime, and optimize equipment performance. This data-driven approach supports continuous improvement and ensures that every batch meets the highest industry standards, from manufacturing consistency to regulatory reporting.

Easy compliance tracking

Ensure seamless compliance by automating data tracking and generating accurate reports.

Improved batch efficiency

Optimize pharmaceutical batch production by minimizing downtime and maximizing equipment utilization

Enhanced quality control

Monitor and prevent deviations in production processes, reducing defects and maintaining product consistency.

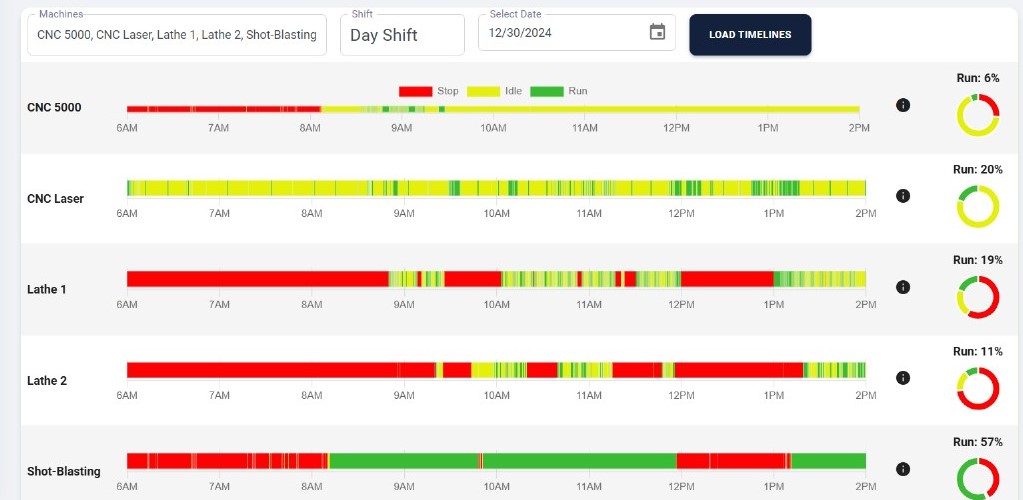

Real Time Process visibility

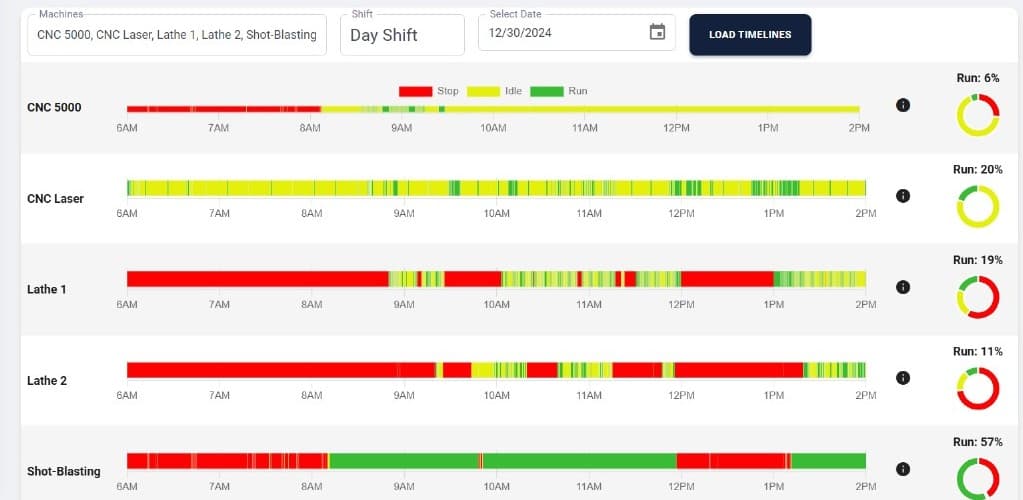

This feature enables pharmaceutical manufacturers to track Unplanned Downtime, monitor equipment efficiency, and quickly respond to deviations to maintain regulatory compliance.

Automatic Tracking of downtime

Through providing context to automatically detected downtime / microstops durations (no human intervention), Changeover, Cleaning and other operations can be improved by identifying abnormal durations related to a specific machine, a specific operator , a specific tool and a specific article / batch.

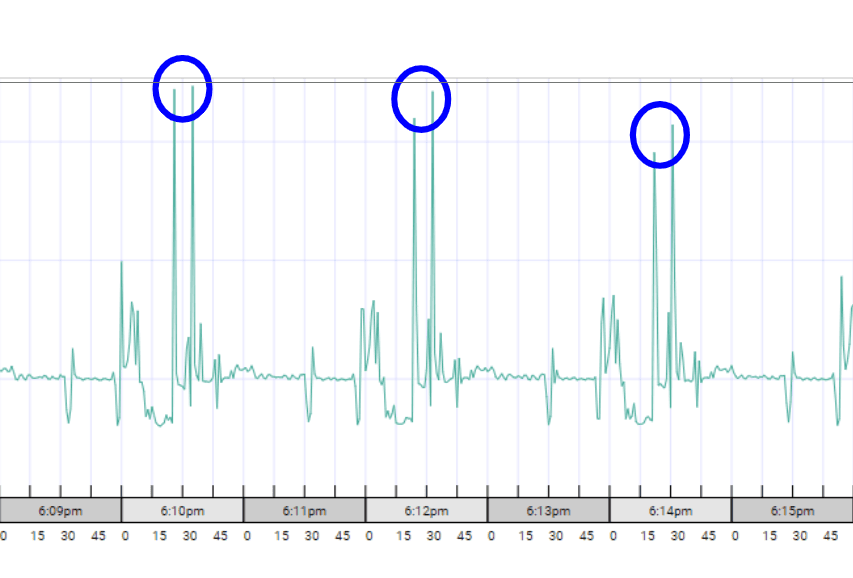

RT automatic Parts /Cycle time tracking

Automate your cycle count data collection. no PLC integration needed. No human input required. Every created part / cycle can be seen through the power profile or through electrical actuators status in machine panel.

Detection and alerts of deviations in manufacturing cycle times.

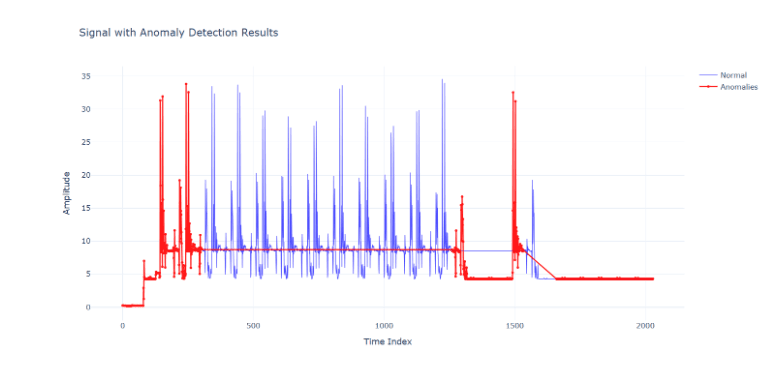

RT production anomalies

Anomalies in production (non-cyclic production, scattered production, malfunction of an actuator ) are reflected into the power profiles during operations. Operators / Managers can detect in time such issues thanks to our AI powered Anomaly detection algorithms.

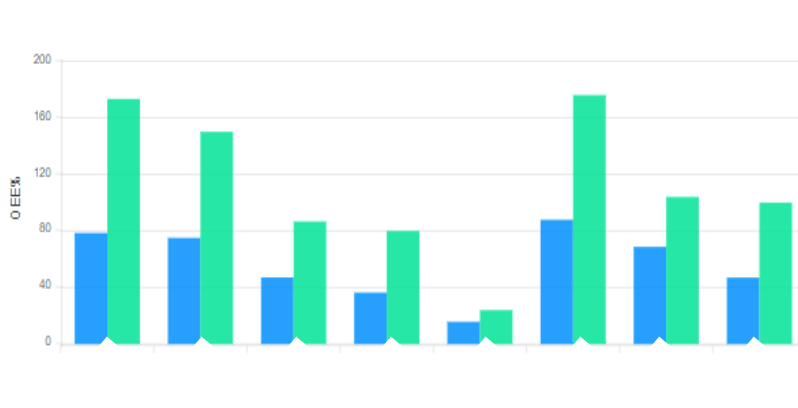

KPIs Analytics

Tracking KPIs in long lines where we have different cells or machines connected to understand who originates the highest inefficiencies in the overall line.

Compare between expected and real results ( cycles, energy costs per unit,....)

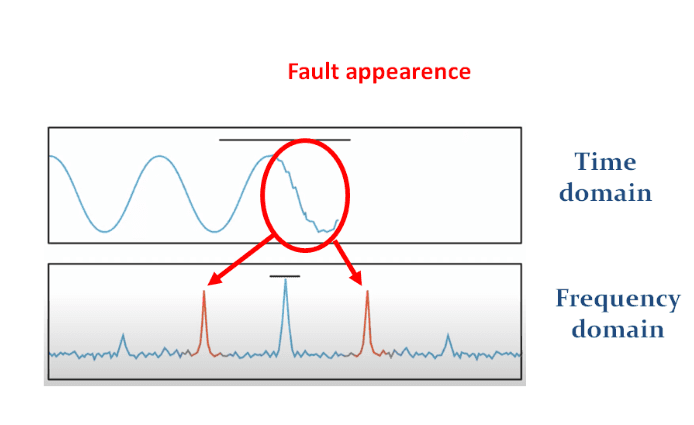

Predictive Maintenance

Identify early signs of fault within Mechanical / Electrical systems of a machine from motor to load.

Why Pharmaceutical industries chose Amperon?

The Challenges

Heterogeneous machines (old and modern) dominate the factory.

Costly process of connecting PLCs.

Inability to track manually micro-stops / abnormal production in time

The Vision: Real-Time OEE Monitoring for Legacy Assets

Expected Impact (ROI in 2 months)

Uptime

through early detection of bottlenecks and killing downtime causes.

Performance

by uncovering hidden performance losses.

Energy Consumption

by avoiding unproductive consumption.

Return on Investment

2 Months

Ready to take your operations to the next level?

Let's talk about how Amperon Technlogies can help your team reduce downtime, boost output, and drive performance across every line, shift, and site.