Bridge the gap to smarter factory operations

Real-time intelligence to optimize production. Simple, same-day setup gives you visibility in hours and impact in days, not months.

Simplifying manufacturing excellence using Amperon's AI-powered FactoryOps platform

We empower small and medium manufacturing teams with unparalleled operational insights and intelligent guidance toward manufacturing excellence for a fraction of the cost of existing monitoring systems.

Install in hours. Results in days.

The fastest way to improve factory operations.

Every factory has opportunities to uncover

Intelligent factory operations shouldn't take all your time or budget. Amperon Technologies reveals the opportunities already inside your operations.

Reduce the paperwork. Start making decisions with real data.

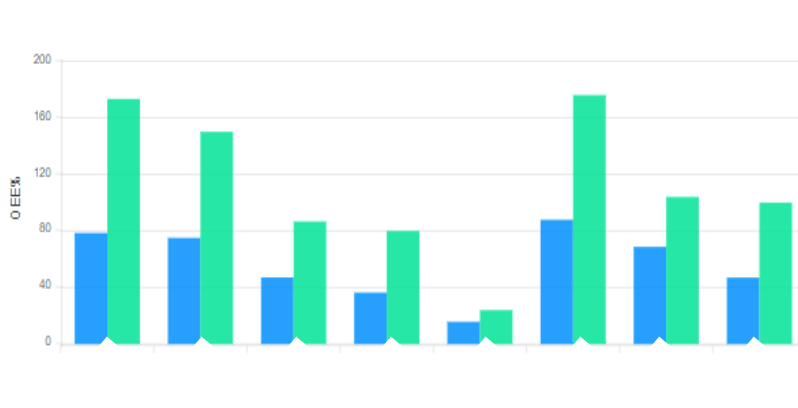

+30%

Overall Equipment Efficiency

-30%

Energy consumption

+40%

On-Time Delivery

-40%

Upfront hardware investment

-70%

Manual data entry burden

x4

Faster integration

3 Steps to Reach Sustainable Peak Performance

Get real-time visibility and insights in minutes — no complex installations required.

1.Clamp

Connect to any machine through low-cost, non-intrusive sensors

2.See

Empower your operators with real-time machine status and AI-powered predictive alerts

3.Understand

Track and improve manufacturing and energy efficiency KPIs through traceability and root cause analysis

GREAT PARTNERS HAVE CONFIDENCE IN US

Start simple, see value fast, scale over time

Non-invasive sensors provide real-time visibility into any machine from day one. Teams can start to reduce downtime and increase OEE, then scale results with AI, integrations, and visibility across more machines and sites.

.gif)

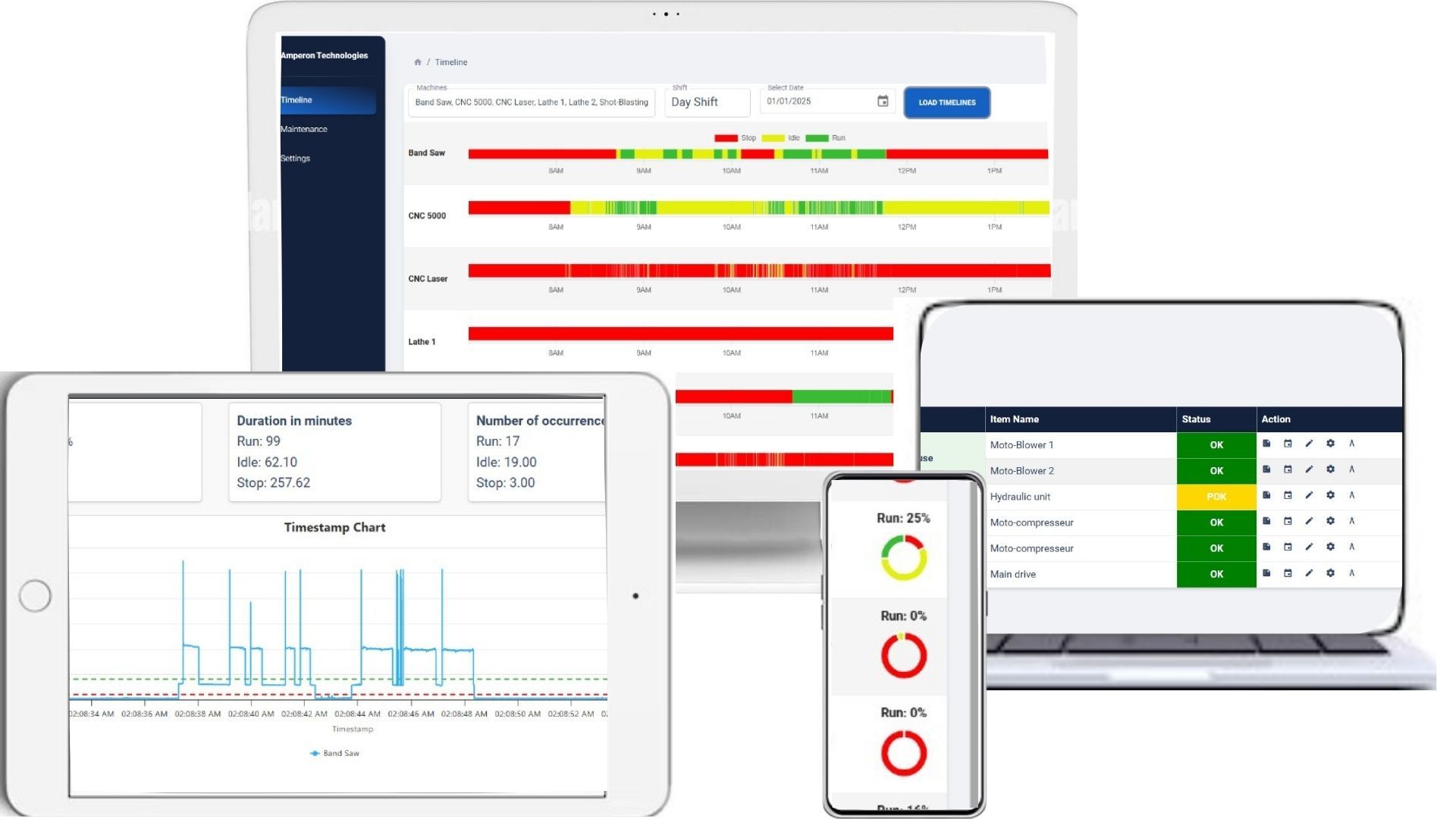

Real-time insights for every machine

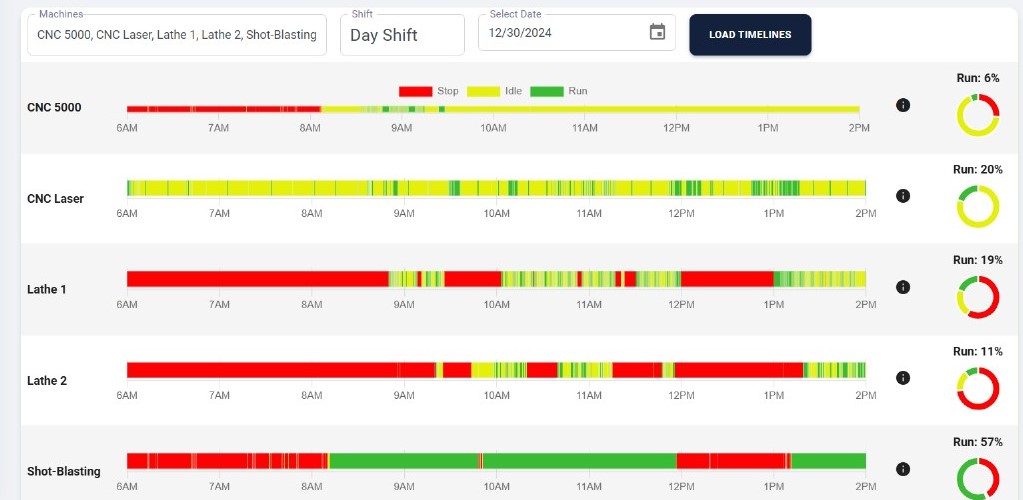

Downtime

Accurately track downtime and root causes to improve utilization and production.

OEE

Monitor OEE in real-time and see trends over time by machine and by plant.

Production

Forecast throughput and accurately track planned vs. actual production.

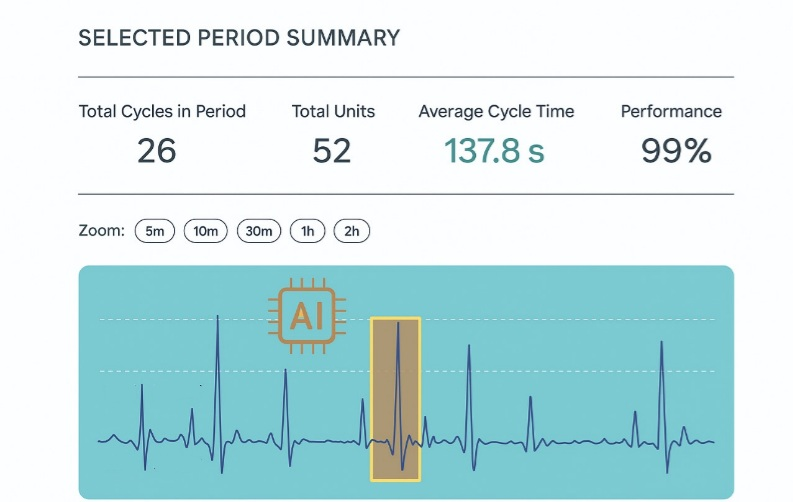

AI-powered Anomaly Detection

Detect issues and predict maintenance needs to stay ahead of machine breakdowns.

Alerts & Reports

Keep a pulse on real-time and historical performance to resolve issues fast.

Cycles

Accurately track cycles, cycle time, and performance against targets.

Energy

Track energy consumption across all of your machines and related costs.

Condition Monitoring

Monitor conditions like temperature, flow, humidity, and pressure.

Compatibility with any machine, regardless of age, model, or process

Our machine monitoring platform uses hardware that connects through external signals, enabling machine integration without relying on PLCs or invasive modifications. This allows us to standardize your data across your manufacturing process.

Packaging

Doypack, case packers, canning machines, baggers, and more.

Filling Lines

Liquid fillers for food, chemicals, and beverages.

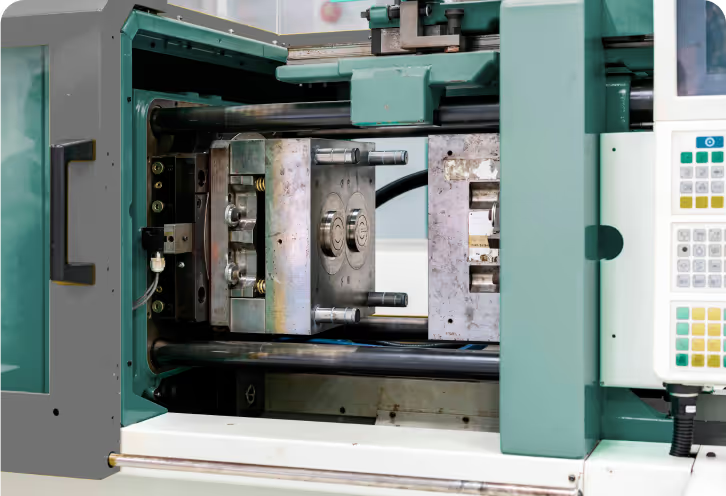

Plastic Machinery

Injection molding, blow molding, thermoforming, extrusion, recycling, and more.

CNC Machines

Presses, benders, punch presses, laser cutters, welders, and more.

Metalworking Machines

Benders, presses, cutting machines, punching machines, welders, and more.

Other industrial processes

Assembly, glass, electronics, textiles, printing, and more.

Expert Industry 4.0 team for agile, seamless implementation

We install hardware and get you online in a single visit, with minimal setup. Our team fine-tunes AI algorithms and adapts the platform to your plant’s specific needs, delivering value from day one.

Why Smart Hardware Matters

Turn machines into data sources, fast

Many machines weren’t built for visibility. That’s why Amperon Technologies hardware makes the difference: it turns analog signals into real-time digital insights.

Simplify machine integration

Our hardware bridges the gap between legacy systems and modern analytics. No retrofits, no reprogramming, just clean, consistent data.

Built for your shop floor

Amperon Technologies hardware and industrial sensors are designed to maintain reliable signal and data capture, even in isolated areas or complex setups.

Boost your productivity

With better data, your team makes better decisions. Use real-time visibility to reduce downtime, streamline operations, and improve output shift by shift.

Building a smart, connected, predictive future together

Rooted in the realities of today's factory floor, Amperon Technologies helps you make smarter decisions today and lay the foundation for long-term operational excellence.

Real-Time Visibility

Fill in operational blind spots and get a pulse on every machine, in every factory.

Predictive Intelligence

Always-on algorithms detect anomalies early and surface issues before they occur.

Enhanced Monitoring

Add on more sensors, condition monitoring, and more for even richer insights.

Smarter Execution

Make data-driven decisions with Amperon Technologies'next-gen MES.

Sustainable Performance

Integrate energy management into daily workflows to reduce waste and lower costs.