FactoryOps for

food & beverage

Whether baking, freezing, packing, and more, Amperon Technologies helps food and beverage teams reduce downtime and increase production.

GREAT PARTNERS HAVE CONFIDENCE IN US

Smarter food & beverage manufacturing

Monitor production in real time and identify when and where efficiency drops–with visibility across shifts, lines and teams

Why choose Amperon Technologies for your manufacturing facility?

Amperon Technologies is trusted by manufacturers to improve performance, reduce losses, and increase visibility on the shop floor. Whether you produce plastics, metals, or pharmaceuticals, Amperon helps teams make smarter decisions in real time.

Real-time monitoring

Gain immediate visibility into your production processes, allowing for swift identification and resolution of issues to minimize downtime.

Enhanced quality control

Utilize automated checklists and reporting to maintain high-quality standards and reduce the risk of product recalls.

Waste reduction

Identify areas of inefficiency to minimize waste, leading to cost savings and more sustainable operations.

Stay on top of every batch

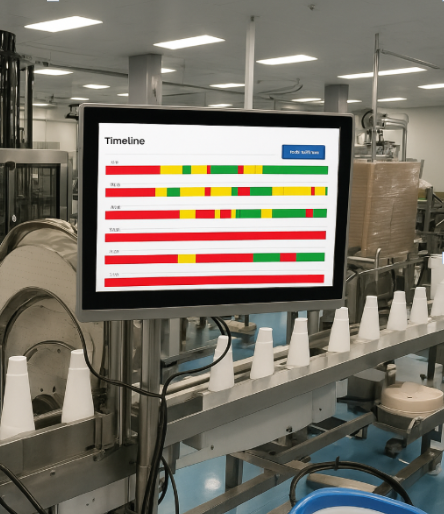

Track production performance in real time across shifts, lines, and machines. Amperon Technologies helps food and beverage manufacturers monitor output, detect issues instantly, and maintain consistency — crucial for meeting strict industry quality standards.

Reduce downtime, boost output

Amperon automatically detects and records machine stoppages, helping manufacturers quickly identify root causes. This feature minimizes unplanned downtime, ensuring smooth production flows and reducing costly interruptions in food processing.

Real-time visibility and alerts

AI-powered FactoryOps Platform strengthens quality control by continuously monitoring the production process and automatically triggering quality checks when they matter most. Results are displayed clearly on a live production timeline, with instant alerts pinpointing when things go wrong. This lets your team react to issues fast, fix them before they snowball, and keep everyone in the loop

Optimizing Energy Consumption

In the agrifood industry, energy consumption is a critical factor impacting both cost and sustainability, with process heat (59%) and refrigeration (16%) accounting for the majority of usage, followed by motor drives, HVAC systems, and lighting. Amperon Technologies empowers agrifood manufacturers to optimize these energy-intensive operations through its AI-powered FactoryOps platform. By analyzing machine-level electricity signals in real time, Amperon helps identify inefficiencies in refrigeration, heating, and motor-driven systems, enabling significant reductions in waste and costs. This not only improves operational efficiency but also ensures compliance with increasingly strict carbon reporting standards, making agrifood production smarter, more sustainable, and more competitive.

Ready to take your operations to the next level?

Let's talk about how Amperon Technlogies can help your team reduce downtime, boost output, and drive performance across every line, shift, and site.